- Spreader Stokers

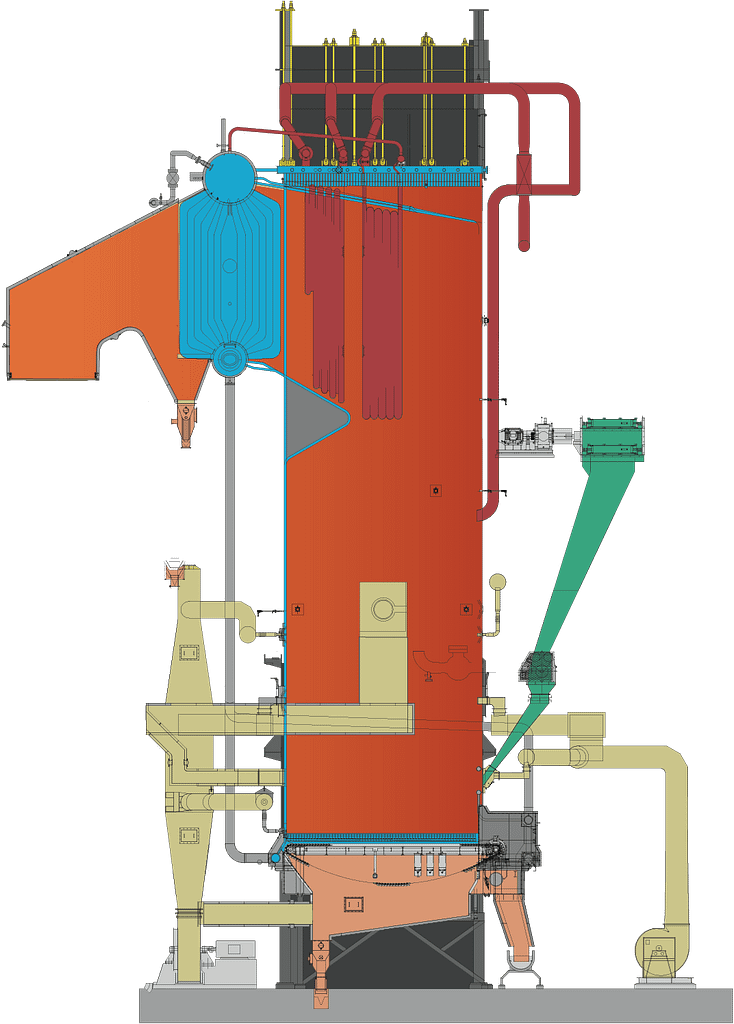

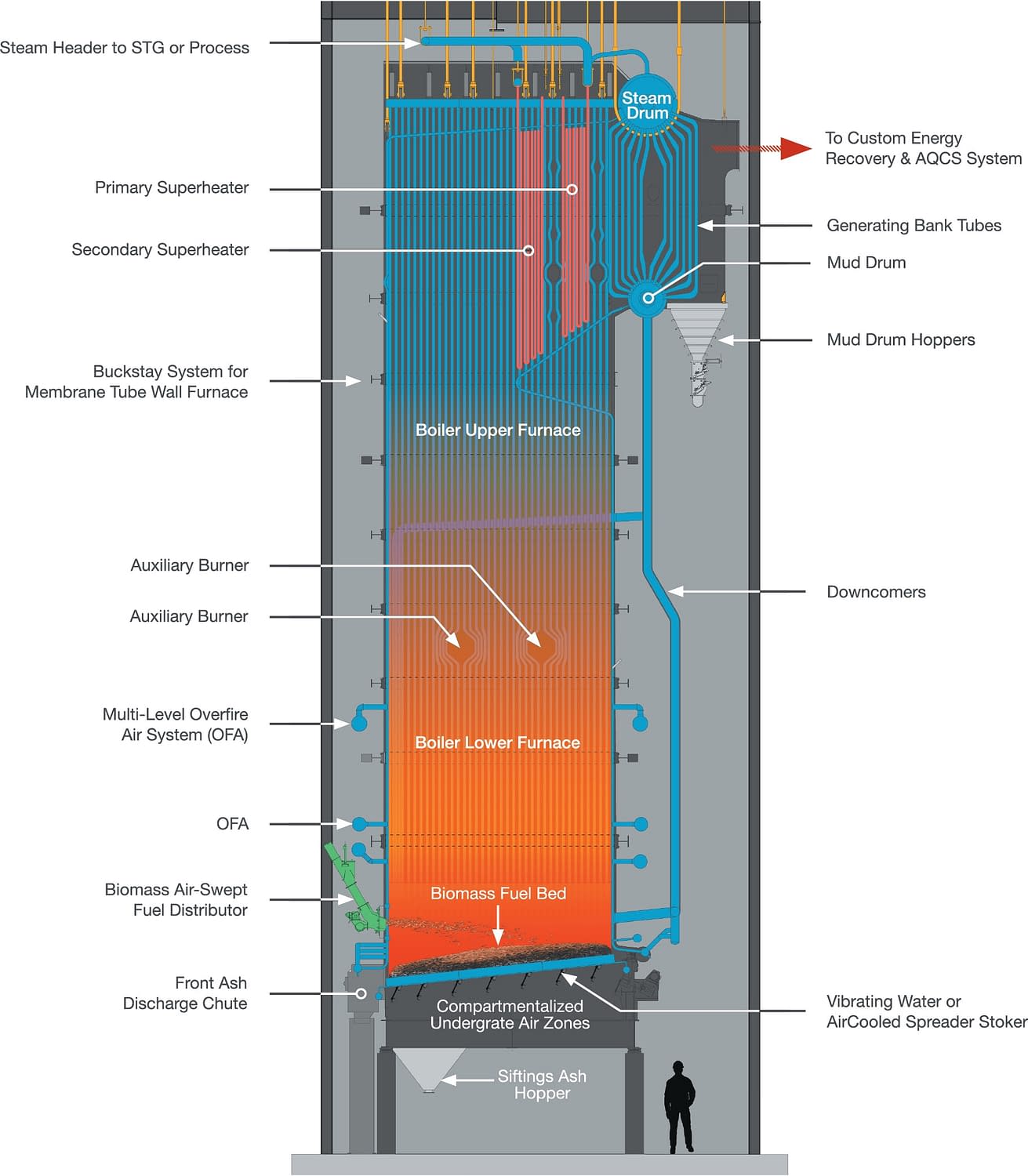

Wellons utilizes the Spreader Stoker in combination with a variety of grate designs – the traveling grate, the air-cooled vibrating grate, and the water-cooled vibrating grate. These configurations are ideally suited to burn all types of biomass with moisture contents up to 60% and low ash content.

Their multi-fuel capability includes wood waste, bagasse, agricultural residues, sludge, fossil fuels, and MSW.

Spreader Stoker

Combustion Principles

Spreader Stoker

Grate Options

Spreader Stoker

Ash Removal

Spreader Stoker

Fuel Capability

Spreader Stoker

Benefits

Designed For Biomass Firing

The Spreader Stoker (combined with a Vibrating or Traveling Grate) is the combustor of choice for large capacity steam applications for steam generation or power generation projects.

Wellons works with its long term, trusted suppliers to provide this combustion technology as part of our integrated package of equipment.

These systems are compatible with existing boiler designs allowing retrofits of older combustors.

Spreader Stoker

Combustion Principles

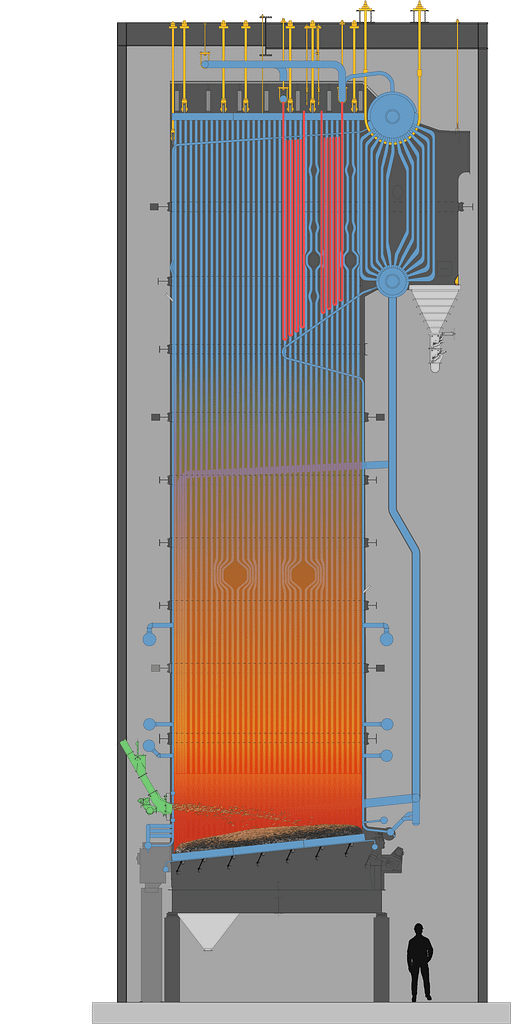

The Spreader Stoker (combined with a Vibrating or Traveling Grate) is specifically designed and engineered based on the boiler operating conditions and the fuel characteristics.

Spreader Stoker

Fuel Feed

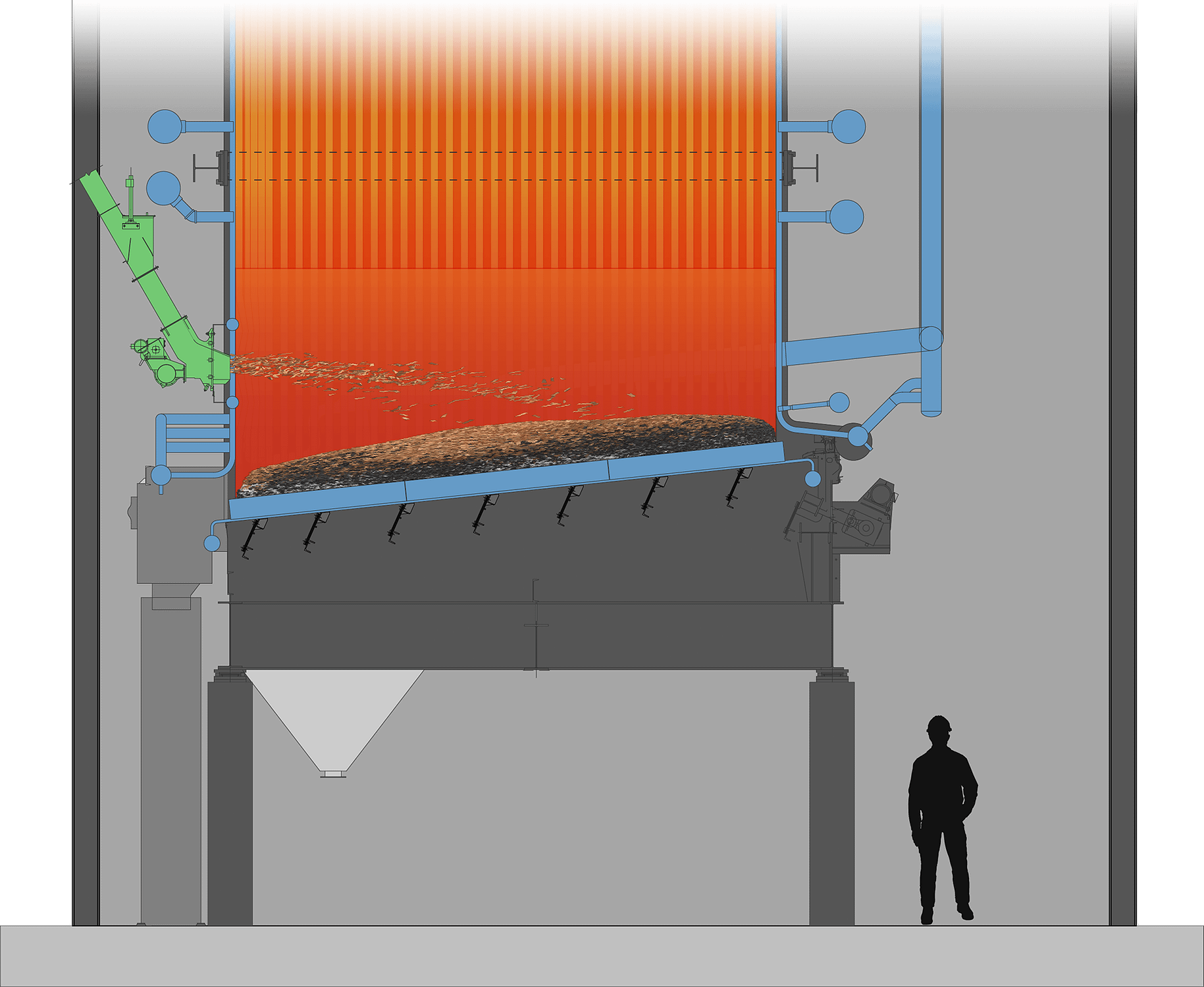

The pneumatic spreader stoker is the most common fuel feed mechanism for the Vibrating and Traveling Grates. An adjustable air swept fuel distributor is used to deposit the fuel into the furnace and on to the vibrating grate.

The fine particles are burnt in semi-suspension mode in the highly turbulent combustion zone.

The coarse particles are spread evenly on the grate surface and are exposed to the under- fire combustion air.

The spreader stoker fuel feed feature enhances the ability of the boiler to handle load swings.

Spreader Stoker

Combustion Air

Combustion air is comprised of Primary Air and Secondary Air.

Primary combustion air is supplied under the grates in zones to enhance combustion control. The primary air can be preheated to facilitate the combustion of higher moisture content fuels.

Secondary combustion air is introduced into the furnace at multiple levels above the grate to complete the combustion process and reduce emissions. Preheat of the secondary combustion air is also an option.

Spreader Stoker

Grate Options

Wellons will utilize either a Vibrating Grate or Traveling Grate depending upon the fuel characteristics, load characteristics and required steam conditions.

Spreader Stoker

Vibrating Grates

The key feature of the vibrating grate is the intermittent vibration which moves the fuel and ash bed down the grate.

The vibration frequency and duration are adjustable and will depend upon the fuel combustion characteristics and the firing rate.

The vibrating grates can be either air-cooled or water-cooled to maintain suitable operating conditions to prevent heat damage to the grates.

Spreader Stoker

Traveling Grates

The forward moving, traveling grate continuously advances via grate chains moving the fuel and ash bed down the grate.

The under-fire combustion air can be zoned to provide better control of the combustion on the grates.

Spreader Stoker

Alternate Biomass Fuel Capability

The Spreader Stoker (combined with Vibrating or Traveling Grate) is a proven performer when it comes to combusting a variety of fuels. In addition to woody biomass, Wellons has the capability of combusting a variety of agricultural residues which meet energy needs and reduce disposal requirements.

Many of these fuels have unique physical and chemical characteristics which require special consideration to ensure clean and efficient combustion as well as the longevity of the equipment.

Depending on potential fuel available, Wellons will conduct combustion testing to evaluate flue gas combustion, composition, and the ash characteristics under varying combustion conditions to determine the correct combustion technology.

Spreader Stoker

Benefits

The Spreader Stoker offers a range of benefits: